Nationwide Factory Relocation

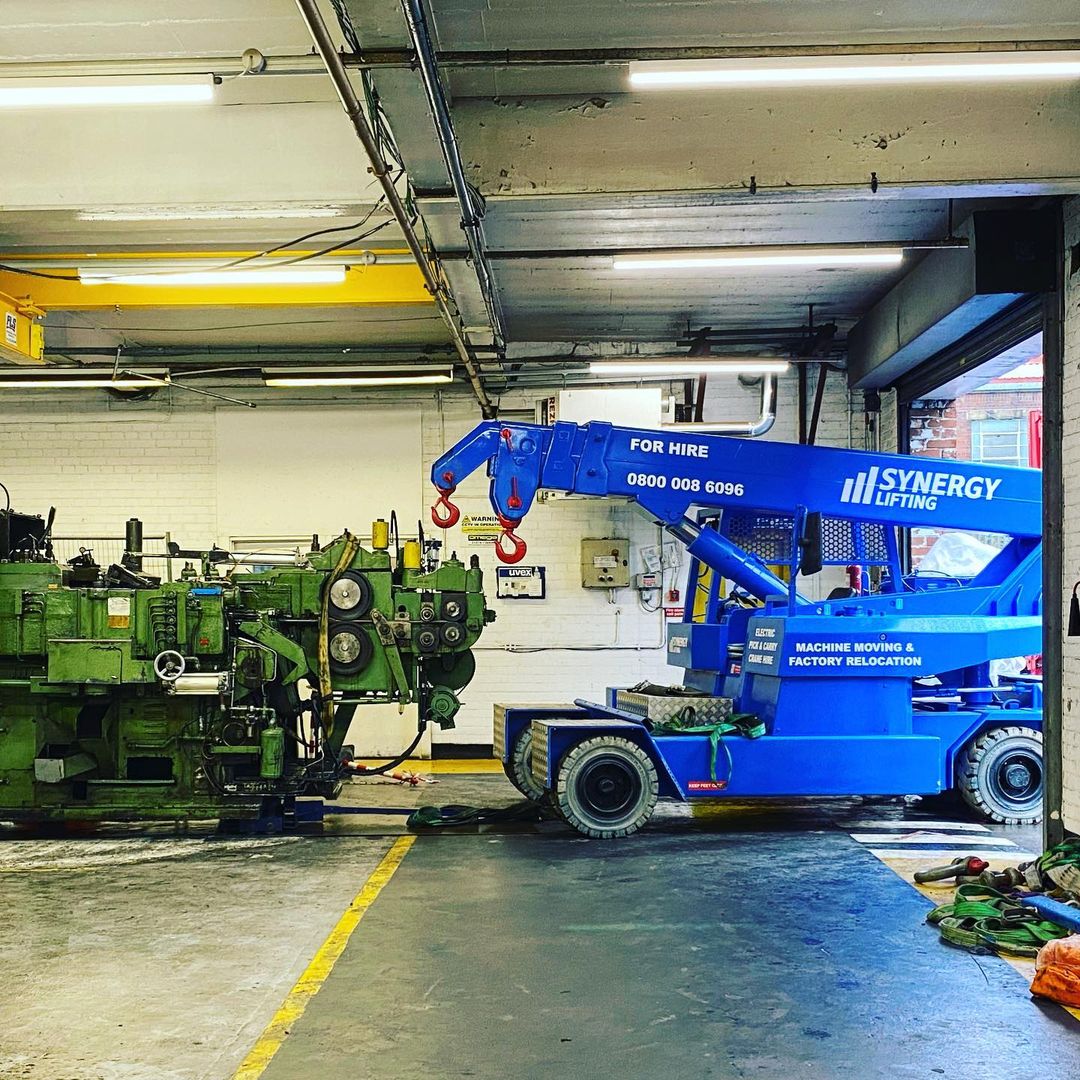

We deliver full turnkey factory relocation services across the UK and Europe, managing every stage from disconnection and dismantling through to transport, reinstallation, and recommissioning at the new site. Our process includes disconnecting and decommissioning equipment, carrying out strip-outs and dismantling, lifting and removing machinery, packaging and transporting it securely, offloading and positioning it at the new location, and completing reinstallation and recommissioning.

Factory relocations involve complex logistics, tight schedules, and safety-critical operations. Working with a specialist team helps reduce risk, avoid delays, and keep your project on track. We bring the experience, equipment, and planning expertise needed to manage relocations efficiently and with minimal disruption.

What area do we cover?

We are spread out across the UK and that gives us nationwide coverage. This means we are able to carry out surveys and take on work wherever you need us.

Not ready for a site visit yet or just budgeting?

Don’t worry, we can do a desktop survey to assess what is needed and provide you with a quote. We can usually do this on the same day you get in touch with us.

What is included in our factory relocation service?

Each factory relocation project is unique and we can combine a range of our services to create a tailored package for your particular factory relocation project requirements.

What sectors do we provide factory relocation services to?

Our team are working nationwide in a range of sectors providing factory relocations, find out what we can do for you.

Contact us

Get In Touch

Please leave a few details and a member of our crane hire and contract lifting team will be in touch to discuss your requirements in more detail.

What is our factory relocation process?

Every relocation is different – some can be completed in a single day, while others unfold over several months. Regardless of scale, each project follows a structured process built around key stages.

Site Visit

The first step is for Synergy Lifting's factory relocation team to conduct a site audit to produce documentation for the following steps.

Quotation

Following our initial site visit, our team will produce a detailed quotation with an outline of our scope of works and timescales.

Site Assessment

Our team will undertake our full site assessment to establish HSE requirements and finalise our method for lifting operations, dismantling etc.

Risk Assessment

With safety being our priority in all of our operations, a site-specific risk assessment will be created to go alongside our method statement.

Method Statement

Our team will write up a site-specific method statement detailing our safe working procedures to carry out our operations.

Highways and Councils

Where required, we can work with local councils to arrange any necessary permits or road closures if heavy/wide loads need transporting off site.

Insurance Covers

Synergy Lifting's full comprehensive insurance covers will be presented to the client for review before site operations commence.

Project Management

The factory relocation work will be undertaken by Synergy Lifting’s qualified personnel utilising our specialist plant and equipment.

Handover

We hand over the project to our client upon completion. This could be after a full factory relocation or a phase of the overall project.