About our asset realisation and rationalisation service

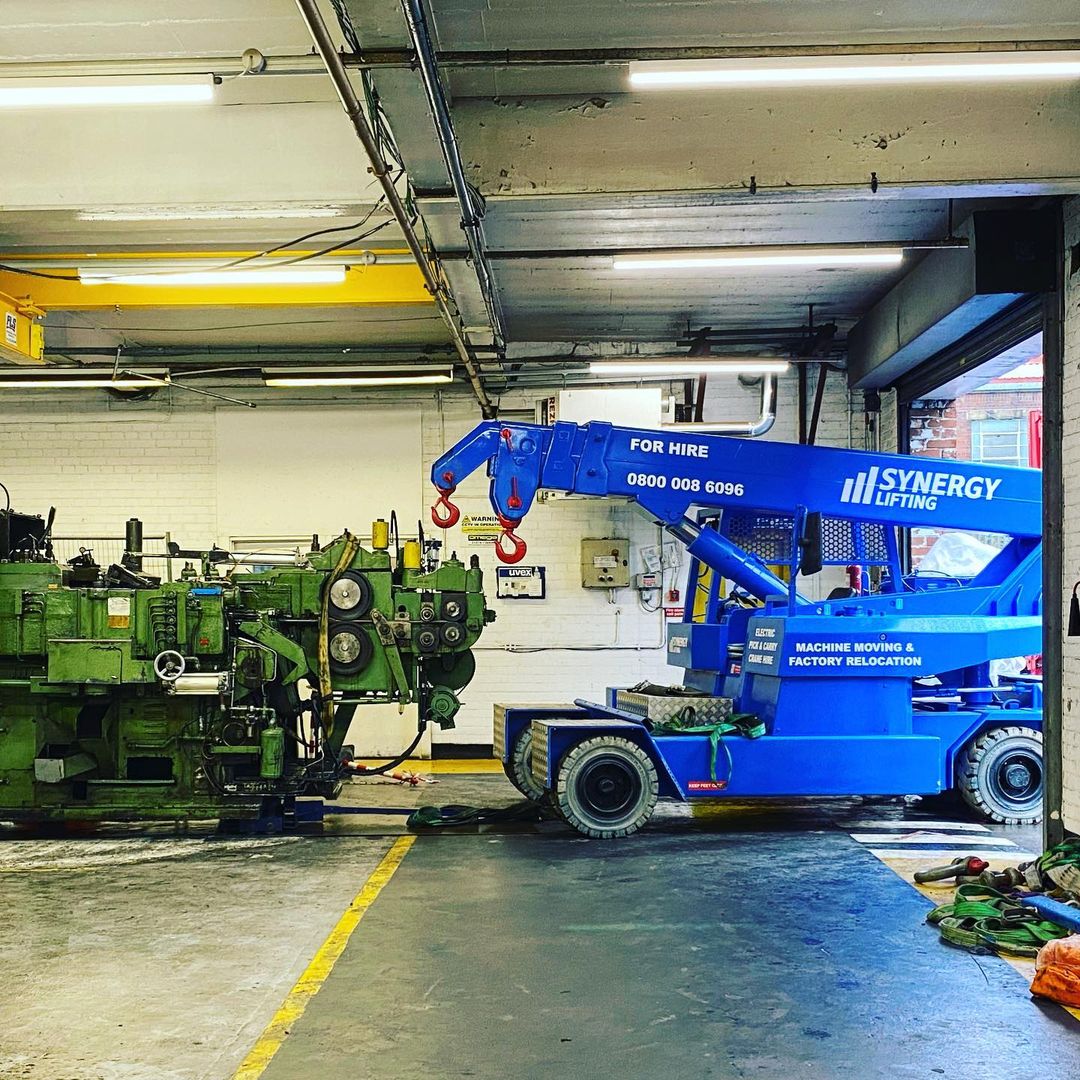

At Synergy Lifting, we offer specialized Asset Realisation and Rationalisation services designed to enhance businesses’ asset management strategies. Our expertise lies in assisting companies with downsizing, decommissioning, or releasing capital as part of asset rationalisation projects. Additionally, we help clients upgrade to new technology by facilitating machinery removals and asset redeployment. Through thorough asset identification and valuation, we provide valuable insights into each asset’s worth, condition, and market demand, enabling informed decision-making for redeployment or disposal. Our focus is on safe, environmentally friendly asset disposal, while maximizing financial returns to support your business’s goals. Trust Synergy Lifting for comprehensive asset optimization solutions tailored to your needs.

What to consider when planning Asset Realisation and Rationalisation?

In addition to the factors mentioned earlier, it is crucial to analyse the potential risks and challenges that may arise during the Asset Realisation and Rationalisation process. Consider the impact of any operational disruptions, regulatory requirements, or logistical constraints that could affect the smooth execution of the project. Collaborating with a seasoned and knowledgeable partner like Synergy Lifting can significantly mitigate these risks. Their experience in handling diverse asset management scenarios equips them to anticipate and address potential obstacles effectively. Moreover, focus on maintaining transparent communication with all stakeholders involved to ensure a cohesive understanding of the project’s objectives and progress. By proactively addressing challenges and fostering open communication, you can navigate the Asset Realisation and Rationalisation journey with confidence, achieving enhanced efficiency and successful outcomes.

Our other services

What types of assets can we help with?

At Synergy Lifting, our capabilities extend far and wide when it comes to machinery. Our versatile expertise enables us to handle a diverse range of equipment, catering to various industries and project requirements. From heavy-duty construction machinery to intricate industrial equipment, we are equipped with the right tools, skilled personnel, and years of experience to tackle any challenge. Whether it’s machine delivery, installation, removal, or redeployment, we take pride in offering top-notch solutions that guarantee efficiency, safety, and successful outcomes. With Synergy Lifting by your side, you can rest assured that your machinery needs are in capable hands.

What is included in our asset realisation and rationalisation service?

In summary, Synergy Lifting’s Asset Realisation and Rationalisation services encompass a comprehensive range of solutions, including meticulous site assessments, safe dismantling, efficient logistics, compliance management, streamlined project coordination, and on-demand equipment retrieval. By entrusting these critical tasks to Synergy Lifting’s expert team, businesses can achieve efficient asset optimization and strategic outcomes in line with their goals.

Comprehensive Site Assessment

Before commencing the Asset Realisation and Rationalisation process, a comprehensive site assessment is conducted to gain valuable insights into the scope of assets involved. This assessment includes a detailed examination of machinery, equipment, and property to determine their condition, specifications, and potential value. By understanding the assets’ current state and location, the project planning can be tailored to meet specific requirements effectively.

Compliance & Documentation

Ensuring compliance with legal and regulatory requirements is paramount in the Asset Realisation and Rationalisation process. Synergy Lifting takes care of all necessary documentation, permits, and approvals required for the transportation and disposal of assets. This meticulous attention to compliance ensures a smooth and hassle-free project execution.

Safe & Professional Dismantling

Synergy Lifting’s expert team ensures the safe and professional dismantling of assets during the rationalisation process. Specialized techniques and equipment are employed to carefully disassemble machinery and equipment, adhering to industry best practices and safety standards. By entrusting the dismantling process to skilled professionals, potential damage to assets and workplace accidents are minimized.

Streamlined Project Management

Streamlined project management is at the core of Synergy Lifting’s Asset Realisation and Rationalisation services. From the initial site assessment to the final asset disposal, a dedicated project manager oversees every aspect of the process. This centralized coordination ensures that the project stays on schedule, within budget, and meets the client’s specific objectives.

Efficient Logistics & Transportation

Efficient logistics and transportation play a critical role in the successful execution of Asset Realisation and Rationalisation. Synergy Lifting’s logistics experts meticulously plan the transportation route, considering factors such as the size, weight, and fragility of assets. Utilizing the appropriate lifting equipment and transport methods, assets are moved securely and efficiently to their designated destinations.

On-Demand Equipment Retrieval

As part of Asset Realisation and Rationalisation, Synergy Lifting provides on-demand equipment retrieval services. This allows businesses to promptly redeploy assets within their organization, maximizing resource utilization and minimizing downtime. With Synergy Lifting’s efficient retrieval process, assets are optimally redeployed to suit the evolving needs of the business.

What sectors have we achieved asset realisation and rationalisation in?

Over the years, Synergy Lifting has established itself as a trusted partner in providing comprehensive Asset Realisation and Rationalisation services across diverse industries. Our expertise and experience have enabled us to successfully cater to a wide array of sectors, delivering tailored solutions to meet the unique needs of each industry. From manufacturing and construction to energy and technology, our adept team has executed successful asset optimization projects, helping businesses achieve their goals while maximizing returns on their valuable assets. With a proven track record of excellence, Synergy Lifting stands ready to support your company’s asset management needs, regardless of the sector you operate in.

Construction

We have carried out factory relocation projects for firms in the construction industry – for example we relocated an entire brick factory from one site to another and we assisted with the installation of new equipment at a new modular homes factory. As well as this, we provide crane hire to firms in the construction industry almost every day.

HVAC Equipment

Synergy Lifting work with both manufacturers and installers of heating, ventilation and air conditioning units. As well as working on site to lift HVAC units into and out of position, we have also done work at various manufacturers’ sites to relocate and install new and used equipment that is used in the manufacturing process.

Automotive

We have provided factory relocation packages and machine moving services to many companies working in the aerospace sector. We moved a flight simulations manufacturer from the south coast to the north west, we have installed overhead cranes at Airbus, we have carried out dismantling works at British Aerospace, and much more.

Aerospace

Synergy Lifting are experienced providers of a range of services in the aerospace sector. For example, we have carried out the installation of overhead cranes and industrial scissor lifts at Airbus. We have also carried out dismantling works at British Aerospace and removed redundant equipment from manufacturing facilities in the aerospace sector.

Rail

Synergy Lifting regularly work in close proximity to rail lines and have worked with firms in the rail sector to assist with a wide range of equipment installation and heavy lifts. We have lifted engines out of locomotives for restoration purposes, disposed of redundant rail equipment, and we have lifted and assembled bridges on rail infrastructure projects.

Power

We have relocated factories for firms who operate in the power sector. We have relocated equipment and machines on electrical power generation sites including biomass power plants and energy-from-waste sites. We have also dismantled and installed wind power equipment and turbines.

Food and Beverages

Synergy Lifting have worked on a range of food and beverage sites across the UK including Greggs, Weetabix, McCain’s, PepsiCo, Hains Daniels, and more. Our work has involved heavy machine movement for food and beverage equipment such as lifting and shifting ovens, coolers, and bottling machines into place uas well as full factory relocation projects.

Paper and Packaging

We have relocated entire factories in the paper and packaging sector and often carry out machine moving services. From print presses to labelling machines, our team have lifted heavy equipment through roof openings and factory entrances and we have relocated equipment from one end of the country to the other end and even overseas.

Plastics and Metals

We are often contracted by equipment manufacturers to assist with the installation of new equipment in the plastics and metals sector. We are also often contracted by firms working in this sector who want to relocate entire production lines from one site to another, whether this is for expansion or to streamline their operations.

Chemical and Scientific

Our team have years of experience in installations for petrochemical producers, pharmaceutical manufacturers and chemical mixing plants involving radioactive material handling. We prioritise health and safety whilst carrying out a cost-effective and efficient machine moving or factory relocation service for companies in this sector.

Industrial

Synergy Lifting have relocated factories that fall under the broader industrial sector. We have experience working with heavy machinery (such as presses, milling machines, lathes etc.) and equipment (such as conveyors, screens, towers etc.). We can relocate single machines, whole production lines or entire factories.

Other

From brick factories to chemical plants, from industrial rail manufacturers to paper mills… Synergy Lifting have worked across a multitude of sectors for client’s across the UK and even internationally. We can plan and carry out a factory relocation project for you no matter which sector you are in.

Contact us

Get In Touch

Please leave a few details and a member of our crane hire and contract lifting team will be in touch to discuss your requirements in more detail.

What is our asset realisation and rationalisation process?

At Synergy Lifting, our Asset Realisation and Rationalisation process is meticulously designed to unlock the full potential of your assets and drive strategic growth for your business. We commence with a comprehensive site assessment, thoroughly analysing machinery, equipment, and property to gain valuable insights into their condition and value. Our expert team then executes safe and professional dismantling, adhering to stringent safety standards and protocols. The next step involves efficient logistics and transportation, where we carefully plan the movement of assets to their intended destinations. Compliance and documentation are prioritized, ensuring a smooth and hassle-free process while meeting all legal requirements. Our streamlined project management, overseen by dedicated professionals, guarantees that your project stays on track and within budget. Furthermore, our on-demand equipment retrieval service enables you to redeploy assets promptly, optimizing their utilization and minimizing downtime. With Synergy Lifting’s proven expertise and commitment, your Asset Realisation and Rationalisation journey will be a resounding success, aligned with your business objectives.

Site Visit

The first step is for Synergy Lifting's factory relocation team to conduct a site audit to produce documentation for the following steps.

Quotation

Following our initial site visit, our team will produce a detailed quotation with an outline of our scope of works and timescales.

Site Assessment

Our team will undertake our full site assessment to establish HSE requirements and finalise our method for lifting operations, dismantling etc.

Risk Assessment

With safety being our priority in all of our operations, a site-specific risk assessment will be created to go alongside our method statement.

Method Statement

Our team will write up a site-specific method statement detailing our safe working procedures to carry out our operations.

Highways and Councils

Synergy Lifting will work with local councils to arrange any necessary permits or road closures if heavy/wide loads need transporting off site.

Insurance Covers

Synergy Lifting's full comprehensive insurance covers will be presented to the client for review before site operations commence.

Project Management

The factory relocation work will be undertaken by Synergy Lifting’s qualified personnel utilising our specialist plant and equipment.

Handover

We hand over the project to our client upon completion. This could be after a full factory relocation or a phase of the overall project.

Your asset realisation and rationalisation experts

At Synergy Lifting, our commitment to excellence in Asset Realisation and Rationalisation is bolstered by essential pillars that define our approach. With a wealth of managerial experience, competent personnel, cutting-edge plant and equipment, and meticulous planning and execution, we ensure the optimal handling of your valuable assets. These key components work seamlessly together to deliver efficient, safe, and strategic asset management solutions, empowering businesses to achieve their goals while maximizing returns on their resources.