01. Project

What we did

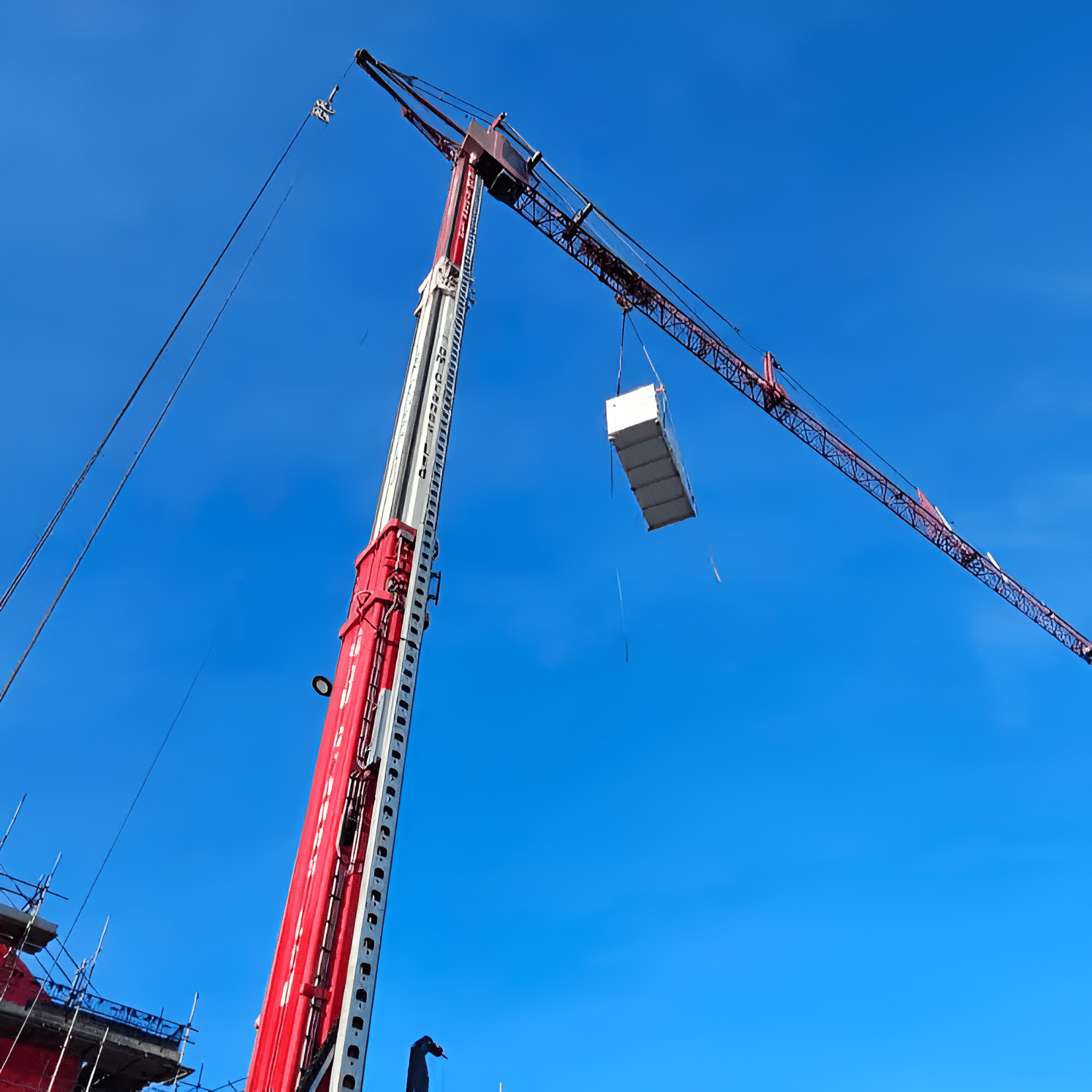

On this project Synergy Lifting were tasked with lifting air handling units (AHUs) into position in a rooftop plantroom.

The plantroom steelwork was already erected and this meant the rafters and beams prohibited us from landing the AHUs into their final positions. To further complicate the matter, the AHUs needed to be positioned on their big foot systems in their final positions but there was not sufficient headroom to set an A-frame gantry up inside the plantroom.

To tackle this challenge, we set up a 60m mobile tower crane alongside the building; we offloaded the AHUs from transport and lifted them through the one available gap in the rafters; we then shifted the AHUs into laydown areas inside the plantroom; next, we raised each AHU up using chain blocks suspended from steel beams via beam clamps and shifted their big foot systems underneath the suspended AHUs; finally, we used pallet trucks to shift the AHUs (whilst on their big foot systems) into their final positions inside the plantroom.

In addition to handling these AHUs, we also lifted up ASHPs, a GRP enclosure and electrical boards too.

02. Resources

How we did it

Plant and Equipment

These particular AHUs arrived fully assembled (i.e. not in sections) and weighed about 2000kg each. The building height was approximately 25m and the reach in towards the roof opening was close to 40m. We therefore chose to use a mobile tower crane to offload the AHUs from transport and lift them in through the roof opening.

Each AHU had 4no lifting points along its base frame so we used the classic combination of bow shackles, web slings, and a modular spreader beam to lift them up. The spreader beam length was adjusted to suit the varying widths of the AHUs.

To carry out the lift and shift operations inside the plantroom, we used a combination of our usual tackle – including pallet trucks, beam clamps, chain blocks, skoots, and jacks.

Labour

Upon receiving this enquiry we arranged a site visit for one of our appointed persons. We then planned the lifting operations and produced a site specific method statement, risk assessment, and illustrated lift plan.

To undertake the job itself, we provided the crane operator, crane supervisor, slinger banksmen, and additional riggers. A comprehensive “toolbox talk” ensured that all personnel were fully briefed on the method statement, risk assessment, and safety procedures prior to the commencement of work.

03. Timeline

Key events

04. Usage

How we can help you

At Synergy Lifting, we know that estimators and project managers at HVAC firms face challenges like unclear costs, choosing the right supplier, tight deadlines, and compliance concerns. We offer clear pricing, expert advice and planning, and efficient mobilisation to meet your deadlines. With our deep knowledge of safety standards, every lift is handled efficiently, economically, and safely – making us a reliable partner for your lifting needs.

Unlike many of our competitors, we were able to undertake the crane lifting operations as well as the lift and shift element on this job. This allowed the work to run smoothly which was particularly important given the the fact there was only one gap in the steelwork to lower equipment through and tight space inside the plantroom for carrying out lift and shift operations. If the work had not been performed efficiently, it could easily have meant the crane would run into the second day and costs would then have increased drastically. We also were able to offer some cost savings because the operatives involved in the crane lifting activities also overlapped into the lift and shift element. In summary, this job was performed efficiently, safely, and economically.

05. Project Gallery

Take a look

Air Handling Unit, Blyth by Synergy Lifting.

Air Handling Unit, Blyth by Synergy Lifting.

Air Handling Unit, Blyth by Synergy Lifting.

Air Handling Unit, Blyth by Synergy Lifting.

Air Handling Unit, Blyth by Synergy Lifting.

WhatsApp-Image-2025-01-16-at-10.50.02_74a3e62e