01. Project

What we did

On this project Synergy Lifting were originally brought in to look at lifting out a magnetic belt conveyor and lifting in a replacement magnetic belt conveyor. However, given that the magnetic belt conveyor was part of a large complex operational plant, the only feasible access to lift it out was through the roof.

As part of our scope of works, we created the roof opening above the conveyor. This involved removing double skin sheets and obstructing purlins. After successfully replacing the magnetic belt conveyor we reinstated the roof. We spliced purlins back together and we also replaced the insulation, fixings, and made sure the sheets were properly sealed.

By taking control of both the contract lifting element and roofing element, we were able to ensure a smooth operation without any issues. This also meant that the financial burden associated with cancelling a 450te contract lift would have been ours had we failed to create the roof opening – fortunately, we planned this thoroughly and know what we are doing so it never came to this.

02. Resources

How we did it

Plant and Equipment

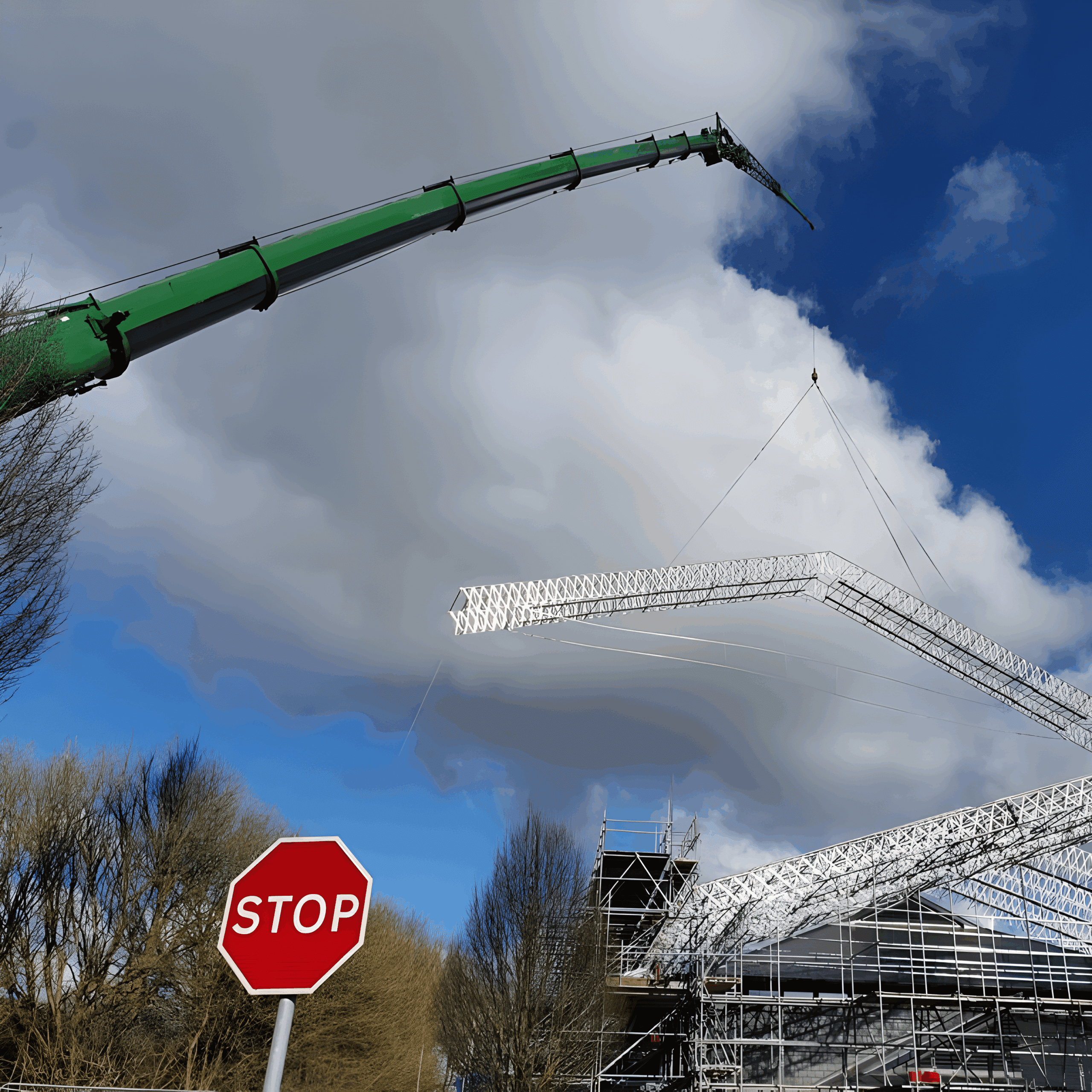

Both the old and new magnetic belt conveyor weighed 6000kg. This weight increased to nearly 7000kg by the time we factored in the weight of the hook and the weight of the lifting tackle. The radius was a whopping 68m which meant this would need a considerably heavy crane to do the lifting.

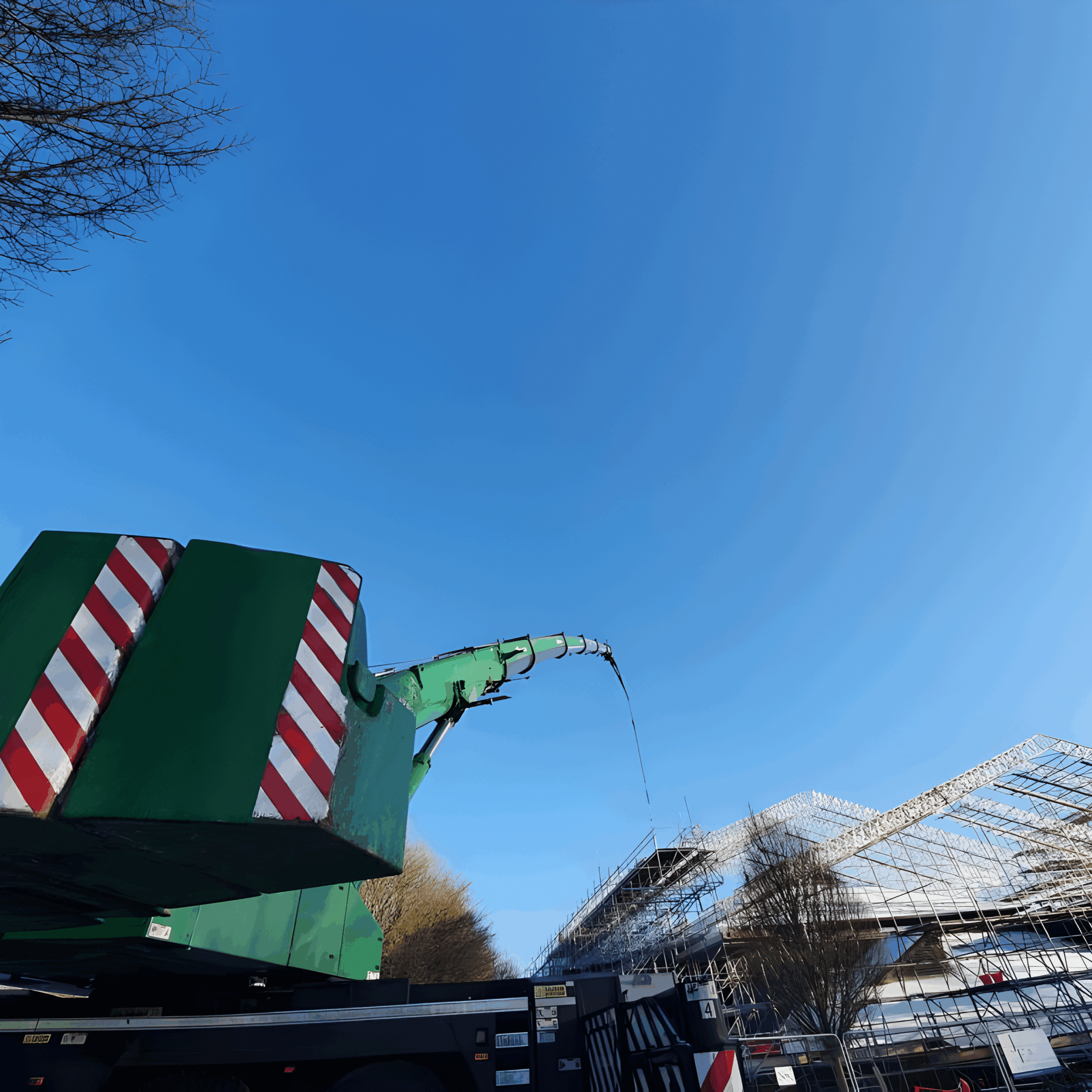

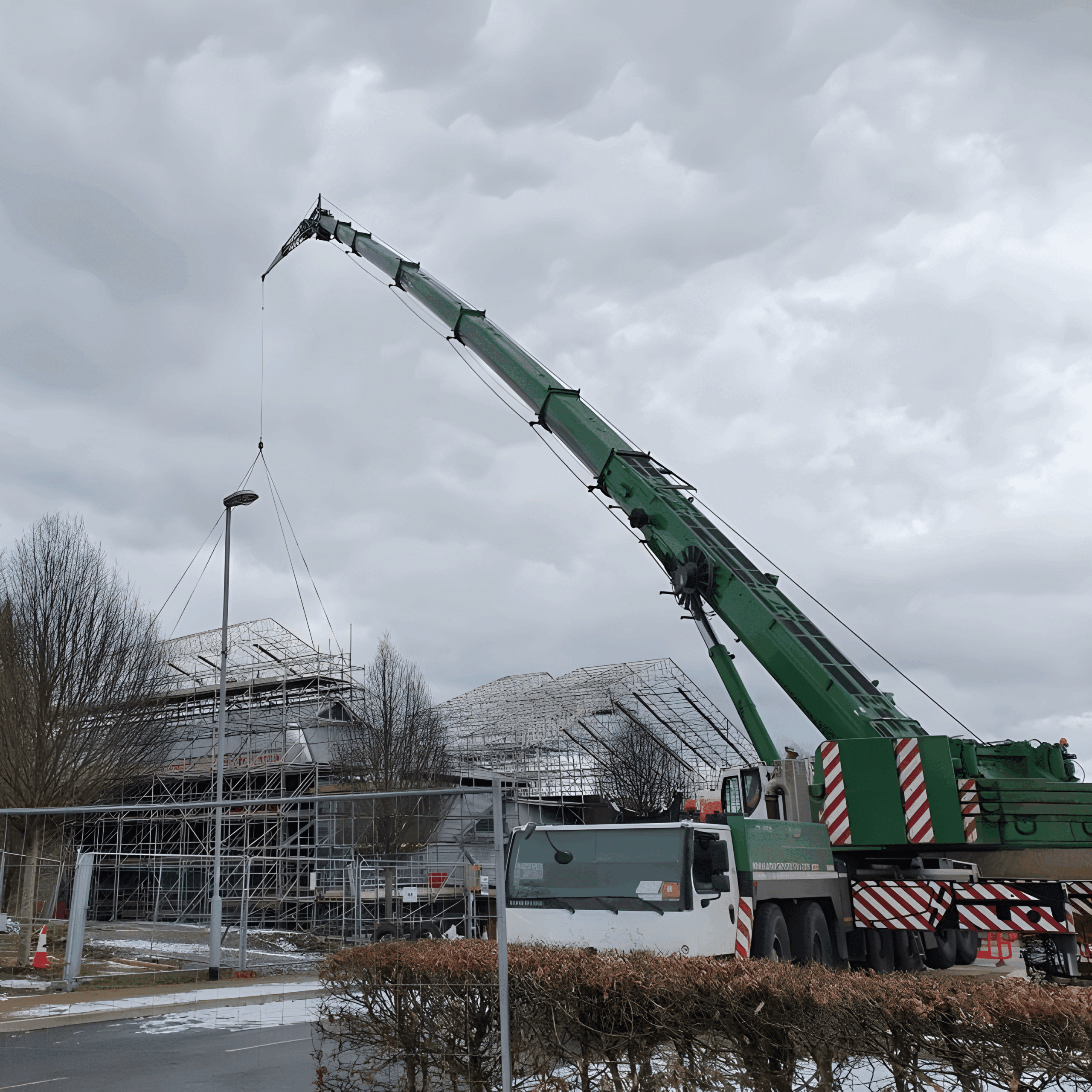

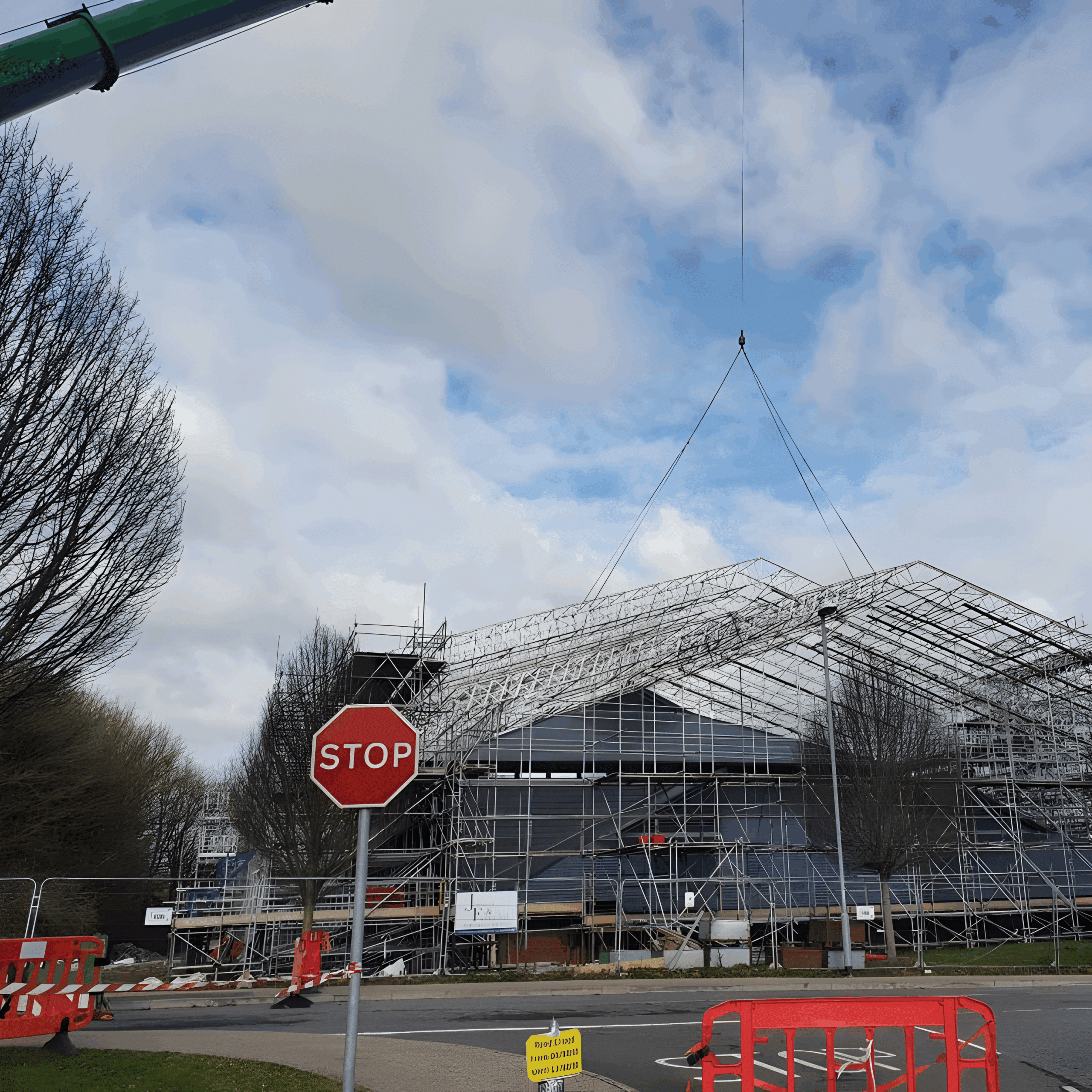

We planned this job with a Liebherr LTM 1450-8.1 set up on full outrigger spread with 134te of counterweight and 77m of main boom telescoped out. As you can see from the photos for this project, our careful planning meant that we narrowly (but comfortably) avoided being jib bound by the building edge.

The outrigger load came in at close to 180te but this was spread out over a 6m2 mat under each outrigger to result in a ground bearing pressure of about 30te/m2.

Labour

Obviously this job went through a lot of careful planning and coordination before it took place. Our appointed person prepared a thorough set of RAMS detailing the contract lifting element and also the roof removal and reinstatement works.

On day 1 our operatives attended site to create the roof opening. On day 2 we removed steel purlins and did the main lifting operations before reinstating the steel purlins. A large part of this day was also taken up for crane mobilisation and demobilisation. On day 3 we reinstated the roof and left site completely.

Our operatives included qualified sheeters, a crane supervisor, a crane operator, an appointed persons, slinger banksmen, and additional riggers.

03. Timeline

Key events

04. Usage

How we can help you

We understand that planned maintenance needs careful planning in advance and that any delays that occur during maintenance works can lead to downtime that can result in astronomical costs for our clients. On this occasion we took control of both the contract lifting and roof work to help mitigate the risk of delays or setbacks that could be caused by having too many separate parties involved in the project.

Synergy Lifting are more than just a crane hire firm and this is why so many of our clients trust us with a wide scope on their maintenance or breakdown projects. When we do have to work alongside other trades, we make sure that our operatives communicate clearly and we make sure everyone is aware of our timeline of work so that it can be integrated well into the overall project programme.

05. Project Gallery

Take a look

WhatsApp Image 2025-02-21 at 14.42.55_758ce780_cleanup

WhatsApp Image 2025-02-21 at 14.42.55_246a72f7_cleanup

WhatsApp Image 2025-02-21 at 14.42.55_62ea8004_cleanup

WhatsApp Image 2025-02-21 at 14.42.55_1e7713cf_cleanup